Applications > Pulp & Paper Industry

GO Systemelektronik supplied the measurement technology for monitoring the wastewater of the packaging manufacturer SOLIDUS SOLUTIONS in the Netherlands.

Water is used in the pulp and paper industry for a variety of processes, for example during paper production to suspend and transport the pulp. In addition, water is used for system cleaning, such as wire and felt cleaning. Even though modern pulp mills can reduce their wastewater to 40 cubic metres per tonne of pulp, the monitoring of wastewater can be attributed great importance.

In particular the high organic load in the wastewater of the pulp and paper industry presents challenging task for biological treatment plants. For this reason, industrial dischargers require continuous monitoring of the Chemical Oxygen Demand (COD) or Total Organic Carbon (TOC). In this way, penalties for exceeding discharge limits or, in the worst case, a breakdown of the treatment plant can be avoided.

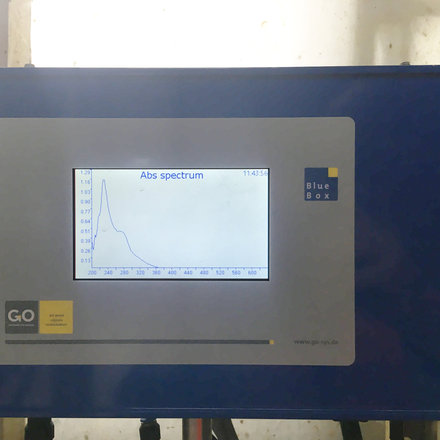

The BlueBox Controller is the heart of the measuring system configuration. It collects all measurement data and makes them available via the integrated modem in the BlueGate Cloud Data Service.

An ISA UV/Vis spectrometer is connected to the BlueBox via an optical fibre. In addition to COD measurement, the sensor enables the simultaneous determination of a large number of other parameters. An extension of the calibration by the parameter Total Organic Carbon (TOC) or other parameters relevant for the operator would easily be possible.

For the monitoring of the industrial wastewater, the ISA UV/Vis spectrometer was integrated via a bypass solution. For this purpose, the measuring head was installed in a flow-through fitting, under which a sample tap was integrated. This allows a sample to be taken for calibration of the system and verification of the measured values at any time and without interrupting the process. The automated cleaning of the spectrometer optics is ensured by an integrated compressed air cleaning system.

The individual parameters are measured every 60 seconds and automatically transmitted to the control room via 4-20 mA. In addition, all data is transmitted simultaneously to the BlueGate Cloud Data Service, so that the measured data are available at any time and from any location via browser. In addition to providing the data, the connection also allows remote maintenance to make changes to the settings if necessary. Thanks to the availability of the data and the possibility of remote maintenance, the ideal time for on-site maintenance operations can be determined. This ensures that the system is always in perfect working order.

SOLIDUS SOLUTIONS offers a wide range of re-useable packaging solutions and is specialized in the production of solid board and solid board packaging in various compositions. SOLIDUS SOLUTIONS supplies many industries, including the food industry, the luxury packaging sector and various other industrial markets.