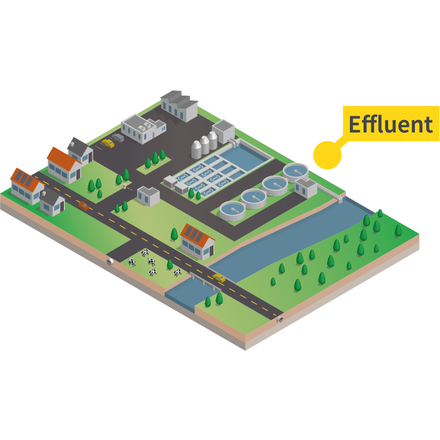

Applications > Wastewater > Outlet

GO Systemelektronik supplied the measurement technology for a municipal wastewater treatment plant to implement the monitoring of the effluent at the outlet of the plant. For this purpose, a spectrometer was installed for continuous measurement of COD, NOx and PO4-P.

A continuous monitoring of the effluent of a wastewater treatment plant is a vital requirement in order to ensure the adherence to discharge limits and requirements of government monitoring.

In addition, high-resolution measurements with short measurement intervals are also indispensable for self-monitoring, as they provide a timely warning when limit values are exceeded and allow for an optimization of the treatment process.

For these purposes, treatment plants require continuous monitoring of parameters such as the Chemical Oxygen Demand (COD), Nitrogen Oxide (NOx), and Orthophosphate (PO4-P), which provide detailed insights into the quality of the treatment process.

Continuous monitoring of the discharge therefore ensures that the quality of the water body into which the treated water is discharged is not negatively affected.

The BlueBox controller is at the heart of the measuring system configuration. The BlueBox is equipped with an ISA UV/Vis Spectrometer, the electronics of which are integrated directly into the controller housing. The measuring head of the spectrometer, which is made of stainless steel is connected connects via an optical fiber.

The controller collects all measurement data and transmits them via an integrated UMTS modem to the BlueGate Cloud Service, through which all measurement data is remotely accessible.

The calibration of the spectrometer for COD, NOx and PO4-P is performed by combining on-site samples and spectral readings.

Based on these data sets a calibration model is created for each parameter, which ensures the inclusion of the specific characteristics of the local water matrix.

To ensure the proper function of the system, the wastewater plant operator has established a remote service contract.

As part of this service offering, the operator receives quarterly reports that indicate the status of the system and provide helpful statements on required actions, such as performing a manual cleaning. In addition, the contract also includes the optimization of the calibration model to include any future changes in the water composition. Therefore, seasonal influences or changes in relation to industrial dischargers can be integrated into the calibration.

The BlueBox controller with integrated spectrometer and modem is mounted in the analysis house directly next to the outlet.

In the analysis house, the treated water from the effluent is pumped into a measuring pot with sample overflow. The ISA sensor head is inserted into the measuring pot via a chain, which ensures the optimal insertion angle and to allow an easy retrieval.

To prevent biofouling or contamination to occur, a compressed air hose is connected the BlueBox, which allows to perform an automated compressed air cleaning of the sensor optics via an integrated valve.

All parameters are measured every 30 seconds and automatically transmitted to the BlueGate data service via UMTS modem. The measured data is thus accessible to the operator at any time. In addition to providing the data, the connection also allows remote maintenance to make changes to the settings if necessary. Thanks to the availability of the data and the possibility of remote maintenance, the ideal time for on-site maintenance operations can be determined. With this information it is possible to ensure, that the system is always in perfect working order.